Description

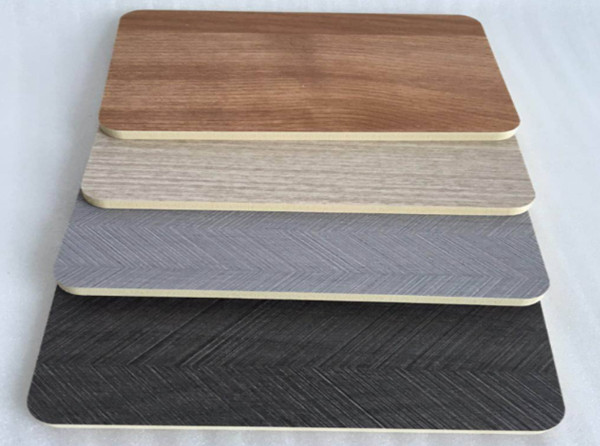

PVC Laminated Board Structure:

1. High-density PVC foam board ( Celuka foam board & WPC foam board) as the substrate.

2. Imported PUR hot melt glue as the adhesive.

3. Covering Laminated film/sheet as the decorative or protective surface on one side or both sides.

Benefits of PUR Lamination

- Virtually seamless visible glue line with no tacky edge

- Excellent balancing when adhering materials to front and back of core

- Superior bond strength compared to contact adhesive and cold press adhesives

- Superior water-resistant bond compared to contact cement and cold press glues

- Excellent machinability

- Manufactured to order in our in-house facility

- We provide fast, easy turn around domestically and internationally