Description

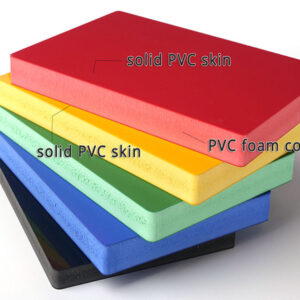

PVC co-extruded Foam Sheet (Polyvinyl chloride co-extrusion foam board) is made with the special co-extrusion production process, technique, and equipment, which forms a sandwich board structure. Both surfaces of the sheet are not foam but rigid, while only the core is foam. It is like a sandwich board with thin surfaces in a one-time process. The advantage of this product is its hard surface like Rigid PVC sheet but in lighter weight and lower cost. Comparing with PVC celuka foam board, PVC co-extruded foam has a smoother and shiny surface. The surface hardness is much better than celuka, which will benefit from using in some application.